Very Simple and Efficient Placer Gold Beneficiation Program

Introduction of Placer Gold Beneficiation Program

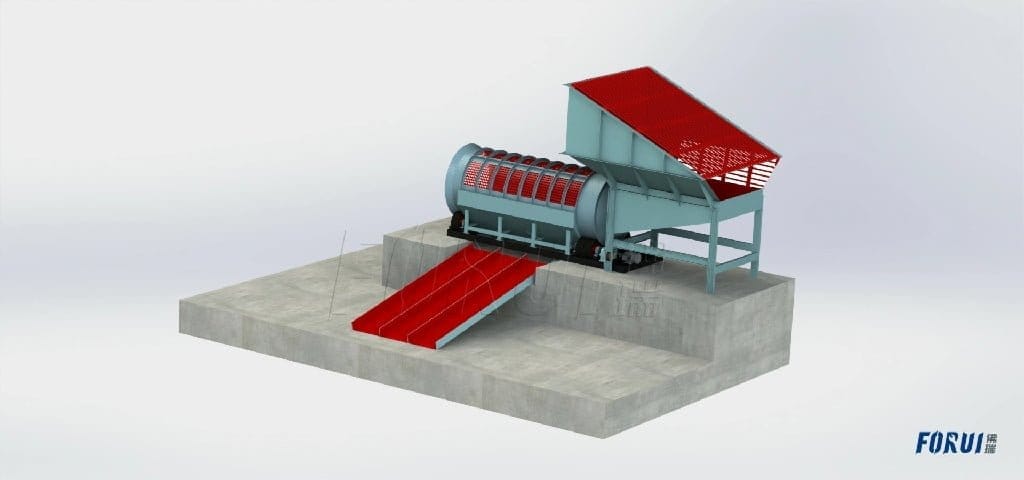

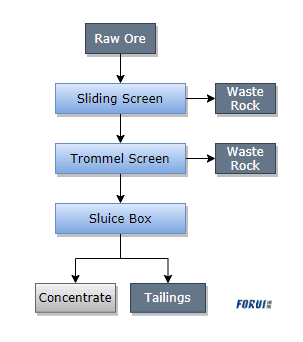

The placer gold beneficiation program introduced today is the most commonly used, the most simple and efficient scheme. There are only two main equipments for the whole program: trommel screen and sluice box. The alluvial gold beneficiation program has the features of low equipment investment, high recovery rate and no pollution.

The most commonly used methods of placer gold beneficiation are: flotation method, gravity beneficiation method, mercury mixing method, etc. Due to its advantages of low cost, high efficiency and no pollution, gravity beneficiation is the most popular method in placer gold ore beneficiation.

Preparation Operation of Placer Gold Ore Dressing

In order to make the particle size of the placer gold ore material reach the feeding size of the ore dressing equipment and give full play to the performance of the ore dressing equipment, it is necessary to pretreat the placer gold ore.

The content of gold in placer gold deposit is very low. In order to extract gold from placer gold, the first thing to do is to separate the gold from the waste rock monomer. For example, in this scheme, a sliding screen and a roller screen are used.

The sliding screen has a simple structure and thick material, which can withstand the impact of large pebbles. Preliminary screening with a slide screen can effectively screen out large pebbles.

Then the material through the bin into the trommel screen, trommel screen has the role of washing ore and screening. The trommel screen divides the placer gold ore into two grades, and the oversize material on the screen is large piece of waste rock, which is directly discarded. The underscreen material enters the sluice box for gravity beneficiation.

Placer Gold Ore Dressing

The equipment used in the ore dressing stage is the dressing sluice box. It is an equipment that uses the gravity beneficiation principle for mineral processing.

In the sluice box, the placer gold deposit is separated by the combined action of gravity, friction and water flow. The flow in the sluice box is turbulent, and its motion forms include two types:

- One is an inclined flow of water parallel to the bottom of the trough

- The whirlpool and stream, which are perpendicular to the bottom of the trough, are upwelling streams. Upwelling loosens the beds and also helps placer gold deposits stratify by density in the water.

As a result of stratification, coarse ore particles with high density are located at the bottom and fine ore particles with low density are located at the top. Driven by the inclined water current, fine-grained minerals with low density are discharged at the end of the sluice box, while the concentrated placer gold ore with high density sinks on the mining gold carpet at the place of the sluice box. Every hour, the mining gold carpet needs to be manually cleaned to obtain placer gold concentrate.

The concentrate obtained by sluice box is crude concentrate product, and they also need to pass through the equipment such as shaking table, mixing barrel, melting furnace and so on, and finally get gold bars, gold ingot and other gold products.

Features of Placer Gold Beneficiation Program

- The sluice box uses water current and the gravity of the placer gold mine to beneficiate materials. It requires no power and almost no production cost.

- The trommel screen can not only wash the ore, but also has a screening effect. It is durable and easy to maintain.

- The whole process has the advantages of low cost, high recovery rate and no pollution.

Thank you for reading. Next time, we will share the “Simple, High-yield Gravity Gold Concentration Program“.

What are your thoughts on the beneficiation plan of placer gold mine? Welcome to leave a message.

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of gold washing plant equipment in Asia. Don’t hesitate to Contact Us, if you have any question of gold washing plant equipment. And welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serve you!

Responses