How to Recover Metal from Silico-manganese Slag

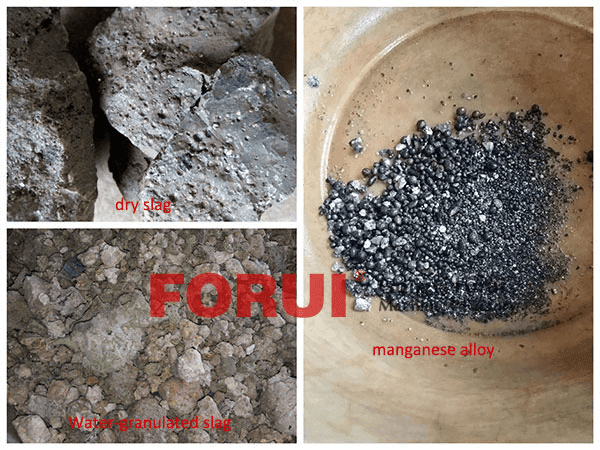

Silico-manganese slag is the solid waste discharged from the silicomanganese alloy smelting furnaces. Since these waste slags contain a certain amount of silico-manganese alloys, the recovery of the silico-manganese alloys can obtain considerable economic returns. Therefore more and more companies and individuals start recycling silico-manganese alloys from these slags.

The silico-manganese alloy in the slag is mostly particles of uneven sizes. To recover these silico-manganese alloys, the slag must first be crushed to dissociate the silico-manganese alloy and the waste slag.

Due to the large difference between the specific gravity of silico-manganese alloy and the specific gravity of waste slag ,using the gravity separation method can easily recover the silico-manganese alloy from slag.

For more metal recovery from smelting slag, please visit our YOUTUBE channel:

[embedyt] https://www.youtube.com/embed?listType=playlist&list=PLiEGXd-0H-lvBTfA5XRdc6YZx1ll0xoBr&v=cpGjPbvbBZ0[/embedyt]The process of recovering silico-manganese alloy from silico-manganese slag mainly consists of jaw crushers, fine crushers, rod mills, mineral jig machines, dewatering screens, etc.

projects:

This video shows the process of mineral jig machines recycling silico-manganese alloy from silico-manganese slag:

Ningxia silico-manganese slag processing project adopts jaw crusher for coarse crushing, fine crusher for fine crushing, mineral jig machine for concentration, linear dewatering screen for dehydration.

This production line processes 500 tons of slag per day, the recovery effect is very good, and it has been well received by customers.

The Hebei silico-manganese water-granulated slag processing project adopts a fine crusher for fine crushing, mineral jig machine for silico-manganese alloy concentration. Since the water-granulated slag generally has no large particles, the production line does not have a jaw crusher. The production line also processes 500 tons of silico-manganese slag per day, has also been recognized and praised by customers.

The silico-manganese slag processing project in Inner Mongolia adopts a jaw crusher for coarse crushing, a rod mill for fine crushing, and a mineral jig for alloy concentration. This production line can process 350 tons per day.

Because this slag has a relatively high hardness, and the traditional fine crusher is too expensive to operate normally for a long time. Therefore, we designed the rod mill fine crushing process for the customer and obtained good results. The customer is very satisfied with the alloy recovery effect.

The Guizhou silico-manganese slag processing project adopts a fine crusher for fine crushing, mineral jig machine for alloy concentration. This production line can process 300 tons per day.

Customers are very recognized and have Ordered 3 silico-manganese slag recovery production lines from Forui Machinery for the second time and maintain a good cooperative relationship.

Gongyi Forui Machinery Factory is a professional manufacturer of silico-manganese slag processing production lines. we have very rich experience in the recycling of silico-manganese slag, we provide free silico-manganese slag recovering experiments, process flow designing, and production line configuration for customers. For more information, please contact us. whatsapp:+8613592513050

Responses