Metal Recovery Process and Plant for Municipal Solid Waste Incineration Residue

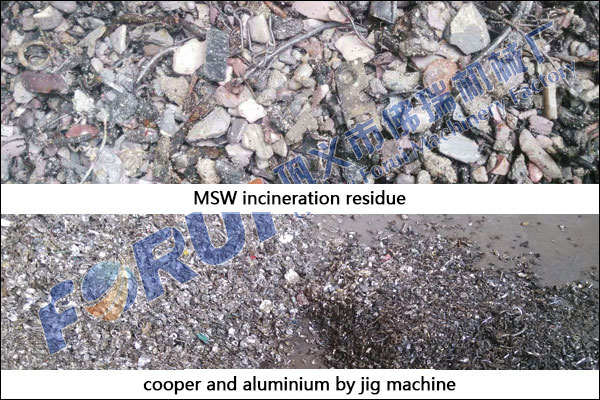

MSW incineration residue is the waste of MSW after high-temperature incineration. The metals in incineration residue mainly include iron, copper, aluminum, zinc, tin, gold, silver, etc. Recycling the metals in the waste residue can get considerable income. How to recycle the metals in the MSW incineration residue?

[embedyt] https://www.youtube.com/watch?v=9vFD0DQn73c[/embedyt]In general, the magnetic material in the incineration residue is firstly recovered by magnetic separators, then the residual metal is recovered by the jig machine, and finally, the aluminum in the jig machine tailing residue is recovered by eddy current. The main metals recovered by the jig machines are copper, tin, lead, zinc, gold, and silver, which have a large specific gravity. Gold, silver, and other precious metals are selected manually, and the remaining metal mixture can be separated by shaking tables.

[embedyt] https://www.youtube.com/watch?v=dzN7lSgBx-E[/embedyt]This is one of metal recovery processes. There are other different processes used to recover metals from MSW incineration residue. As for which process and equipment to use, it should be decided according to the actual situation.

Forui is a professional separation equipment manufacturer. We have rich practical experience in the separation of copper and aluminum from waste materials and metal recovery from incineration residue. We have an experimental platform, which can carry out small-scale separation test for customers, if you want more information, don’t hesitate to contact us at Whatsapp/phone: +8613592513050

Responses