High-yield, High Enrichment Ratio Placer Gold Processing Scheme

1. Introduction of Placer Gold Processing Scheme

In the previous article, we shared “Simple, High-yield Gravity Gold Concentration Program“. Today we are going to share a high-yield and high-enrichment ratio placer gold processing scheme.

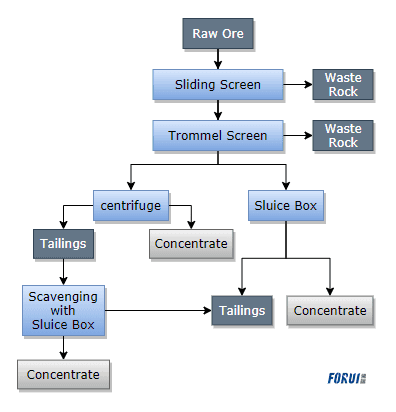

From the plan, we can see that compared with the previous plan that uses a jig machine for beneficiation, today we use a sluice box and a centrifuge as the beneficiation equipment in this plan. Let me share the details of this placer gold beneficiation plan.

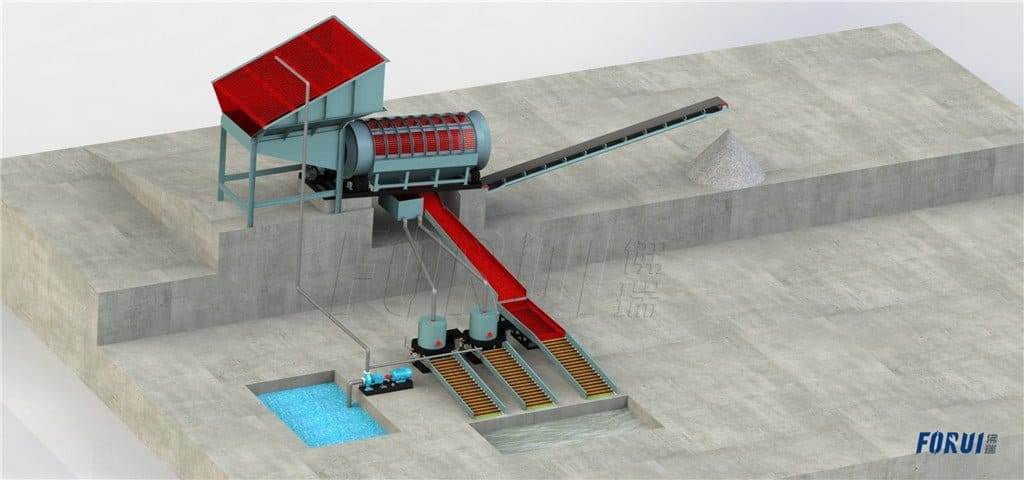

2. Major Equipments

Slide screen, hopper, belt conveyor, trommel screen, sluice box, centrifuge, water pump, etc.

3. Preparation Operation of Placer Gold Processing Scheme

3.1 Screening With a Sliding Screen

Sliding sieve refers to a kind of static and inclined sieve, which relies on the material’s own weight to produce relative sliding on the screen surface for screening.

In this scheme, the sliding screen is used as the primary screening equipment for the beneficiation of placer gold ore and is suitable for screening large pebbles. The whole screening process does not require power, and it has the advantages of simple structure, low cost, convenient adjustment and high efficiency.

With the flushing device, the disadvantages of some placer gold mines due to high mud content are solved well.

3.2 Hopper

After the primary screening, the raw ore is sent to the hopper, which can improve the production efficiency of beneficiation. Because it can temporarily store part of the placer gold ore, the beneficiation process can be carried out continuously.

3.3 Screening With a Trommel

Trommel screen is a kind of machinery which is widely used in the mineral processing technology. It is used to control the mineral processing by the particle size. The screening precision is very high.

As the material will be rolled over in the trommel, the material stuck in the mesh can be timely ejected, so as to effectively prevent material blocking the mesh (screen hole).

The trommel divides the placer gold ore into three particle levels. The oversize product on the screen are large pieces of waste rock and pebbles in the placer gold mine, which are directly discarded.

The two particle levels of the undersieve will be sent to the sluice box and centrifuge for beneficiation.

4. Placer Gold Processing

4.1 Use a Sluice Box for Beneficiation

After the sieving action of the trommel, a part of the sieve enters the sluice box for beneficiation.

The sluice box is a kind of artificial river channel, which uses the gravity and flowing water force of the material to beneficiate.

Because the specific gravity of gold in placer gold is relatively large, the average is between 17.5-18. This value is much larger than the sand in the placer gold ore. Placer gold mines are stratified according to the difference in specific gravity in this kind of water flow.

The sand with low density is in the upper layer, which belongs to the tailings and is finally discharged from the tailings port with the flow of water.

The dense gold particles descend, and in the lower layer of the sluice box, they will be caught by the sticky gold blanket under the sluice box. Generally, the concentrate on the sticky gold blanket needs to be cleaned every hour, and then enter the next beneficiation cycle.

4.2 Use a Centrifuge for Gold Beneficiation

After the sieving action of the trommel, another part of the undersieve enters the centrifuge for beneficiation.

Centrifugal concentrator refers to the equipment for gravity concentration of ore particles in the centrifugal field. It is one of the most efficient gravity dressing equipments.

High centrifugal force is generated when the centrifuge rotates at high speed, which intensifies the process of gravity separation and makes the recovery of fine ore particles more effective.

Its emergence successfully solved the problem of full recovery of fine minerals. Therefore, it is widely used to recover placer gold, tungsten, tin, iron and other minerals.

4.3 Use a Sluice Box for Tailings Scavenging

Since gold has a high economic value, in order to prevent the gold from being lost to the tailings of the centrifuge, a sluice box is used to scavenge the tailings of the centrifuge. This can further improve the recovery rate of placer gold ore beneficiation.

As mentioned above, the process of using trommels, sluice boxs, and centrifuges to beneficiate placer gold ore is continuously carried out under the action of water flow.

Next, the concentrate obtained by gravity beneficiation is sent to amalgamation barrel, amalgam distiller, low-frequency melting furnace, high-frequency melting furnace and other equipments to obtain final gold products such as gold bars and gold bricks.

5. Features

The Gravity Gold Concentration has a lot of features below:

- The sluice box is used in conjunction with the centrifugal concentrator, which has a high recovery rate and enrichment ratio.

- Wide range of feed size. For beneficiation of difficult-to-select fine placer gold ore, the recovery rate can be as high as about 90%.

- The enrichment ratio is very high. Small footprint and high degree of automation.

- No pollution to the environment, it is the future development trend of the placer gold beneficiation industry.

Thank you for reading. What are your thoughts on the beneficiation plan of placer gold mine? Welcome to leave a message.

You may also be interested in the following articles:

- Very Simple And Efficient Placer Gold Beneficiation Program

- Simple, High-YIELD Gravity Gold Concentration Program

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation. And welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serve you!

Responses