An Introduction to Placer Gold Recovery Methods

The principle of placer gold recovery methods is to use gravity dressing method first. The gravity dressing method can recover the gold and its associated heavy minerals from the raw ore to the greatest extent. The gold and various heavy minerals are then separated from each other by a combination of gravity dressing, flotation, mercury mixing, magnetic and electrostatic dressing. So as to achieve the purpose of comprehensive recovery. Placer gold ore dressing is generally divided into break down, screening, desliming and dressing process.

BREAK DOWN, DECOMPOSITION AND SCREENING

Many placer gold ores contain cementitious aggregates, some of which are larger than 100 mm in size. If the mud mass does not break, it will be removed along with the waste rock during the screening process. It’s easy to lose gold. In addition, the cement can cement on gravel or pebbles. Failure to break will also result in loss of gold during the sieving process.

In the gold mining ship, the break down and screening work is completed together in the TROMMEL SCREEN. The TROMMEL SCREEN is provided with intermittent spiral Angle steel. When operating, the washing pressure in the TROMMEL SCREEN should not be lower than 35 kpa. For fixed concentrators on land, washing deposits need to be set up for breakdown and screening. Two water guns are used and rinsed repeatedly in diagonal direction. Outlet pressure of water gun is not less than 20 kpa.

The screening operation can remove 20-40% of the waste rock (gravel, pebble), which is an indispensable operation for placer gold dressing. The determination of reasonable screening parameters must be based on the granularity of gold in the original ore. At present our country placer gold mine chooses screen hole to be 10-20 mm commonly. If the fixed VIBRATING SLUICE BOX is used to do coarse selection equipment, the screen hole can be larger, but not more than 60 mm. Fixed concentrator screening equipment for more than grizzly, vibrating screen.

Gold mining ships use a trommel screen. Screen flushing can not only improve the screening efficiency, but also further break down the cement. So placer gold ore screening operations for water screen. The water screen flushing amount shall be determined according to the requirements of ore washing, and shall meet the concentration requirements of ore dressing operation in the next stage as far as possible. If the VIBRATING SLUICE BOX is for rough beneficiation, the water flow should be 8-14 times the amount of placer ore.

DESLIMING

Materials less than 0.1 mm in placer gold ore deposits generally contain little or no gold. For example, in the Hunchun gold mine, gold of less than 0.1 mm accounts for 0.18 percent, while the same-grade slime accounts for 13.77 percent of the original ore. Gold of less than 0.1 mm, commonly known as floating gold, is difficult to recover during the mineral processing. However, the same size of slime has a disturbing effect on mineral processing, especially on mechanical processing. Therefore, in the mechanical concentrator of placer gold ore, always try to remove the slime less than 0.1 mm. The commonly used desilting equipment in production is desilting bucket of various specifications. And the VIBRATING SLUICE BOX gold selection allows the material granule size width, and the handling capacity is large. Thus the VIBRATING SLUICE BOX does not desilt before ore dressing.

DRESSING

It has been proved by practice that gravity beneficiation is the most effective and economical method to treat placer gold ores. Due to the different particle size composition of gold in the placer gold ore deposits, the effective particle size limits of various gravity processing equipments are also different. Therefore, the reasonable process of placer gold ore dressing should be the joint operation of several gravity dressing equipments.

The gold concentrate obtained in the rough beneficiation stage has a gold grade of 100g/ton, and the heavy placer minerals are mostly above 1-2 kg/ton. At present, there are three methods for the beneficiation of gold containing rough concentrate:

1. Using gold pan to wash gold grains and discard heavy sand.

2. Use a mercury mixing cylinder to mix mercury inside, and discard the heavy sand after obtaining the amalgam.

3. After artificial panning or amalgamation to extract gold, heavy sand shall be sent to concentrate plant for beneficiation. Various kinds of heavy placer minerals were recovered by magnetic and electric separation.

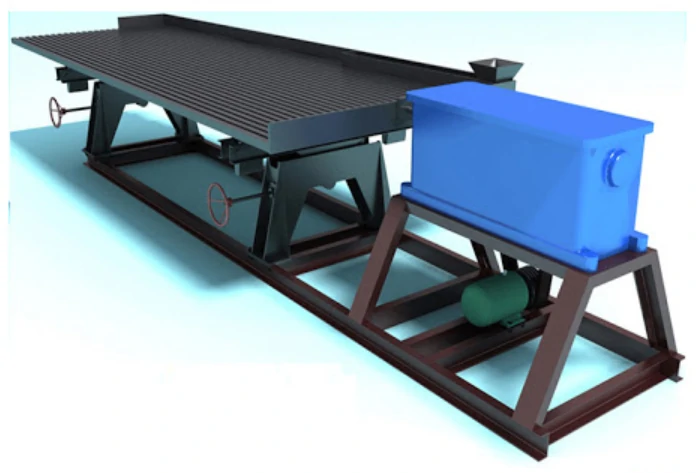

The gold recovery rate of alluvial gold deposit: 70-74% for two-stage VIBRATING SLUICE BOX, The VIBRATING SLUICE BOX is used for rough ore dressing, and the fine process of CENTRIFUGAL CONCENTRATOR and SHAKING TABLE is 75-80%.

Gongyi Forui machinery factory, founded in 1986. We are one of the leading suppliers of beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation. And welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serve you!

Responses