How to Ensure the Effect of Placer Gold Extraction by Jig Machine

Overview

The mineral processing result of placer gold in the jig depends on the following factors:

- The nature of the placer gold.

- Equipment performance.

- Beneficiation solution.

- Equipment operation methods.

Today we mainly share what are the operation methods of the jig machine and how to judge whether the jig machine layer is normal.

What are the Operating Methods that Affect the Placer Gold Extraction by Jig Machine

1. Feeding

The homogeneity of the selected raw materials is an important condition for ensuring the stability of the jigging system, reducing equipment overload or insufficient load, and improving mineral processing efficiency.

2. Frequency and Amplitude

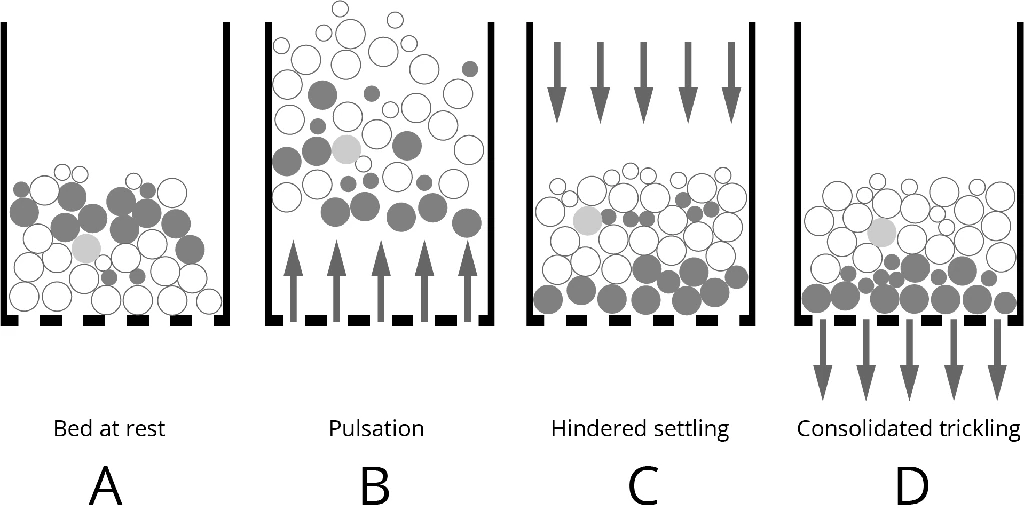

The amplitude of the pulsating water flow determines the height and loose conditions of the mineral bed during the ascent, and the frequency determines the time experienced by a jigging cycle.

3. Air Volume and Water Volume

The air volume can change the amplitude of the pulsating water flow, thereby adjusting the looseness of the mineral bed and the suction force of the screen. The water used by the jig concentrator is divided into topwater and flushing water. The function of flushing is to moisten the feedstock and transport and sort materials, and the flushing volume is about 20% to 30% of the total water volume. The function of the topwater is to supplement the amount of water under the sieve, thereby enhancing the ascending water flow and weakening the descending water flow.

4. State of the Mineral Bed

The movement state of the mineral bed determines the effect of the density layering of the ore particles. Therefore, it is necessary to keep the mineral bed in a state conducive to sorting and stability.

5. Product Emissions

The materials that are layered according to the density should be discharged from the jig in a timely, continuous, and reasonable manner.

How to Judge Whether the Jig Machine Mineral Bed is Normal

It can be judged whether the bed is normal or not by tactile means such as probes.

- Each jigging cycle must be completed, that is, the bed should be dense before the next jigging cycle starts, otherwise the ideal beneficiation result will not be obtained.

- The mineral bed vibrates vigorously, the upper and lower strata vibrate without disconnection, and the gap between the upper and lower strata is very beneficial to fine particle sorting.

- The changing rhythm of layering tight-loose-tight is obvious.

- Sufficient suction when the water flow drops.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us:

- Whatsapp: +8618026978087

- Email: asa.guo@foruimining.com

- Tel: +86-371-64391589

- Facebook: https://www.facebook.com/ForuiMachinery/

- Instagram: https://www.instagram.com/foruimining/

- Twitter: https://twitter.com/ForuiMachinery

- LinkedIn: https://www.linkedin.com/in/asa-guo-benefication-equipment-at-forui/