Barite Washing Machine, Barite Washing Equipment, How to Purify Barite

Overview

The main component of barite is barium sulfate, which is widely used in counterweights, oil wells, papermaking, medical and other industries, but most of the barite needs to be purified before it can be used in industrial production. Today we share with you the barite beneficiation method and barite beneficiation equipment. If you have any questions, please feel free to contact us.

Barite Beneficiation Method

The following is the delivery and processing site of our customer’s barite dressing production line:

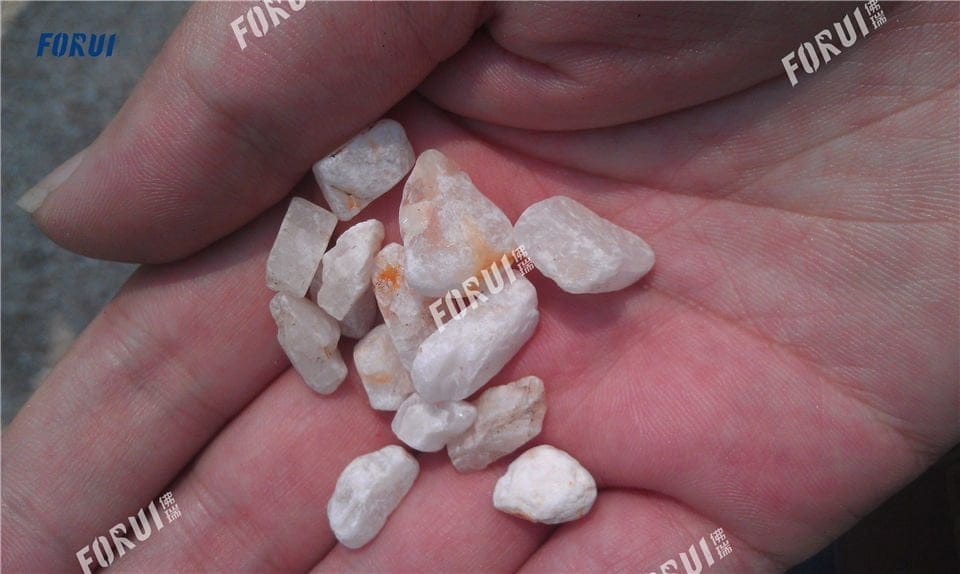

The beneficiation method of barite is mainly gravity beneficiation, supplemented by flotation. Due to the influence of market conditions and selling prices, few people currently use flotation methods to process barite. So we will share the gravity beneficiation process of barite. The following picture shows the effect of gravity beneficiation method and gravity beneficiation equipment after beneficiation:

The gravity beneficiation method can not only process coarse-grained barite, but also has the advantages of small investment in beneficiation equipment, low beneficiation cost, high beneficiation efficiency, and no pollution to the environment. Therefore, the gravity beneficiation method is suitable for most barite concentrators. At present, our customers in many countries and regions around the world use the gravity beneficiation method to process barite, which is used to improve the grade and specific gravity of barite, and all have achieved ideal beneficiation effects. Fory Machinery has provided hundreds of sets of barite beneficiation equipment for barite beneficiation plants in Asia, Africa, Latin America and other countries, and has won unanimous praise from customers for its perfect product quality and excellent after-sales service. , To become a leader in the barite beneficiation equipment manufacturing industry in Asia.

Barite Gravity Mineral Processing Equipment

The equipment generally needed for gravity beneficiation of barite are crushers, vibrating screens, jigs, dewatering screens, etc. The principle of gravity beneficiation is based on the specific gravity difference between barite and associated gangue for beneficiation. The specific gravity of barite is 4.2-4.6, and the specific gravity of the gangue associated with barite is mostly less than 3.0.

Therefore, theoretically speaking, only the process design and equipment configuration need to be carried out according to the requirements of gravity beneficiation, the gravity beneficiation of barite The method can achieve a good beneficiation effect. The core equipment for the gravity beneficiation method to beneficiate and purify barite is the jig, so other auxiliary equipment needs to be configured according to the requirements of the jig beneficiation.

First of all, the choice of crusher needs to be configured according to the requirements of jigging beneficiation. Since the jig machine is suitable for the beneficiation of granular materials, the effect of mineral beneficiation is not good for the minerals that are not finely classified, and the lump and powdery materials coexist. Therefore, it is necessary to avoid the generation of powdery materials in the crushing process.

When selecting equipment, it is necessary to avoid the use of hammer crushers, high-efficiency fine crushers, and other crushing equipment, because they are prone to produce too many powdery materials. Simple and practical jaw crushers and roller crushers should be used as much as possible. Then, the crushed material is sent to the screening process.

Secondly, the selection of screening equipment should also meet the requirements of the feed size of the jig machine. The range of particle size that the jig machine can handle is 0-10mm, 10-30mm and 30-50mm, so the selection of screening equipment should also screen the material into the best feed size of the jig machine according to the actual situation. The screened materials should be transported to the front silo of the jigger with a belt conveyor, and an electromagnetic vibrating feeder for uniform feeding should be set below the silo.

Finally, because the jig machine uses water as the beneficiation medium, the concentrate and tailings it produces contain a large amount of water. In order to facilitate transportation and storage, the concentrate and tailings of the jig machine must be dehydrated. Most of the dewatering equipment uses linear dewatering screens with simple structure and reliable work.

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. We can design and manufacture professional barite processing equipment for you. Welcome to visit our company. We are dedicated to serving you! If you need equipment quotation and process flow, please feel free to Contact Us:

- Whatsapp: +8618026978087

- Email: asa.guo@foruimining.com

Responses