The Most Practical Pyrite Beneficiation Plant, Pyrite Beneficiation Process

The main component of pyrite is FeS2, which is the main raw material for the manufacture of sulfuric acid. Because of its large specific gravity, it is often used as a filler. The specific gravity of pyrite is 4.9-5.2, and its beneficiation method is mainly gravity beneficiation. In recent years, the price of pyrite has soared, making the pyrite beneficiation market very hot. Here are some of the most practical pyrite beneficiation processes for the reference of related parties!

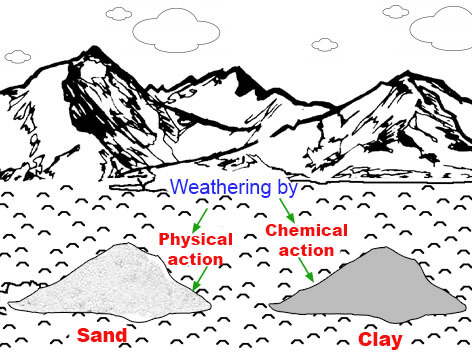

The specific gravity of pyrite is relatively large, and the particle size of the inlay is coarse, and the specific gravity of the associated gangue is generally small. Therefore, using the difference in the specific gravity of pyrite and waste rock for gravity separation can obtain an ideal beneficiation index. The gravity beneficiation process is also the most commonly used pyrite beneficiation process at present.

For the beneficiation of low-grade fine-grained pyrite ore, the flotation process can also be used, but the flotation process requires a large investment in equipment, high operating costs, and pollution to the environment, which has been greatly restricted in recent years. However, the equipment investment of the gravity beneficiation process is small, the operating cost is low, and there is no pollution to the environment, so more and more people are using the gravity beneficiation process.

1. Pyrite Gravity Beneficiation Process

The particle size of pyrite is generally coarser, especially for coal-based pyrite, which is generally coarser and harder. The beneficiation of this kind of pyrite basically adopts gravity beneficiation technology. In the entire process, the raw ore is first crushed to the extent that the pyrite and waste rock are separated, and then it enters the jig for separation. A good beneficiation index can be obtained after one sorting, and the grade and recovery rate of the concentrate can meet the needs of customers.

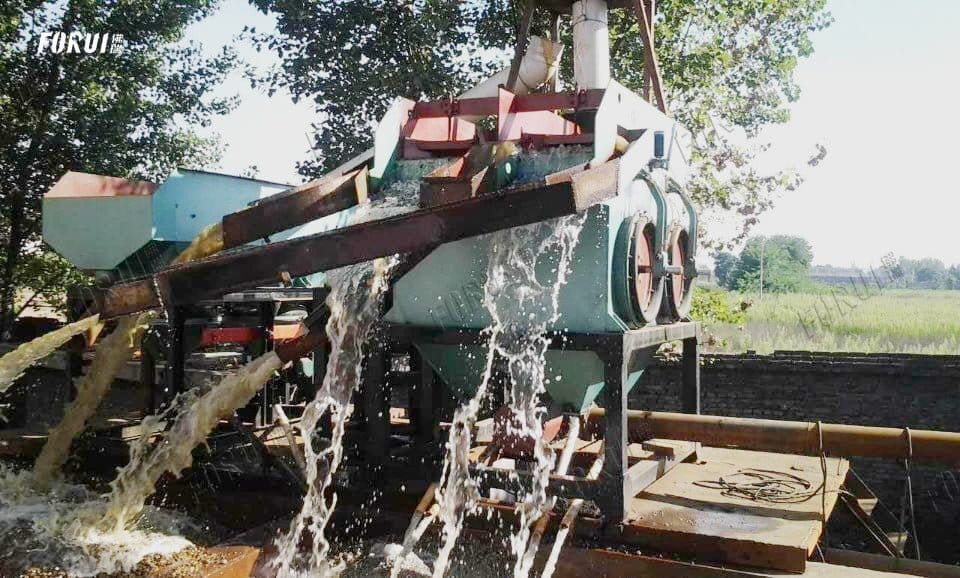

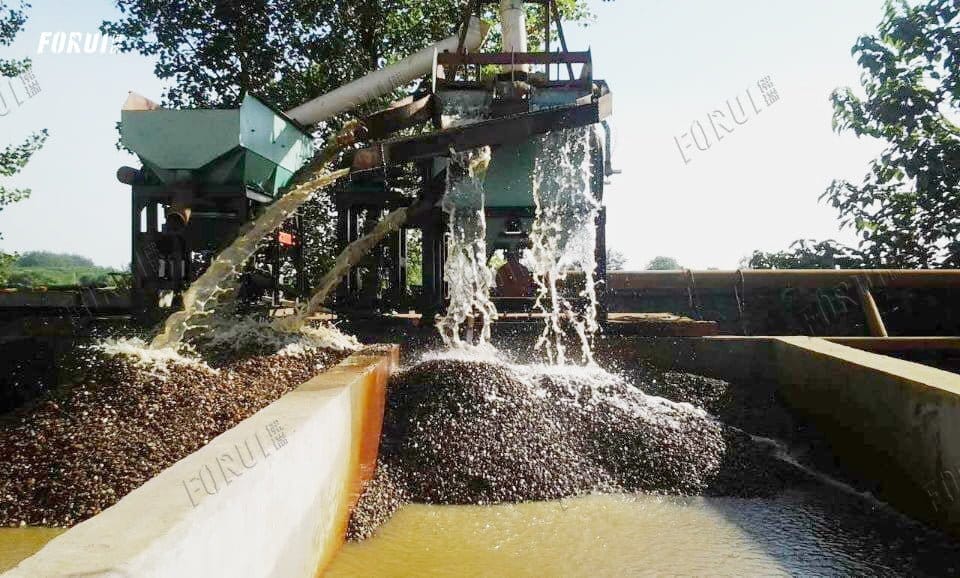

Pyrite Gravity Beneficiation Plant

Pyrite Gravity Beneficiation Plant

Pyrite Gravity Beneficiation Plant

Pyrite Gravity Beneficiation Plant

Pyrite Gravity Beneficiation Plant

The pyrite gravity beneficiation process has the advantages of energy saving, high efficiency, environmental protection, etc., equipment investment is small, and the operating cost is low. It has become one of the most important methods for pyrite beneficiation. It is widely used in new-type pyrite concentrators. The beneficiation equipment used is mainly a jig, and sometimes a shaker is also used.

2. Pyrite flotation process

The flotation process can be used for the beneficiation of low-grade pyrite with finer grain size. Pyrite belongs to easy-float minerals, and the flotation process can be completed by using a simple flotation process, and the beneficiation index is relatively high.

Flotation equipment includes crushers, ball mills, classifiers, flotation machines, etc. However, the investment of flotation process equipment is large, the operation cost is high, and there is a certain degree of pollution to the environment, and its use has been restricted in some areas.

Gongyi Forui Machinery Factory is a professional manufacturer of mineral processing equipment. The factory produces complete sets of mineral processing equipment such as jigs, magnetic separators, flotation machines, etc., and designs mineral processing flow and equipment configuration for customers. If you have any questions, please feel free to contact us. Contact number: +8618026978087.

Responses