Spiral Chute and Spiral Concentrator for Alluvial Gold

1. Structure of Spiral Concentrator for Alluvial Gold

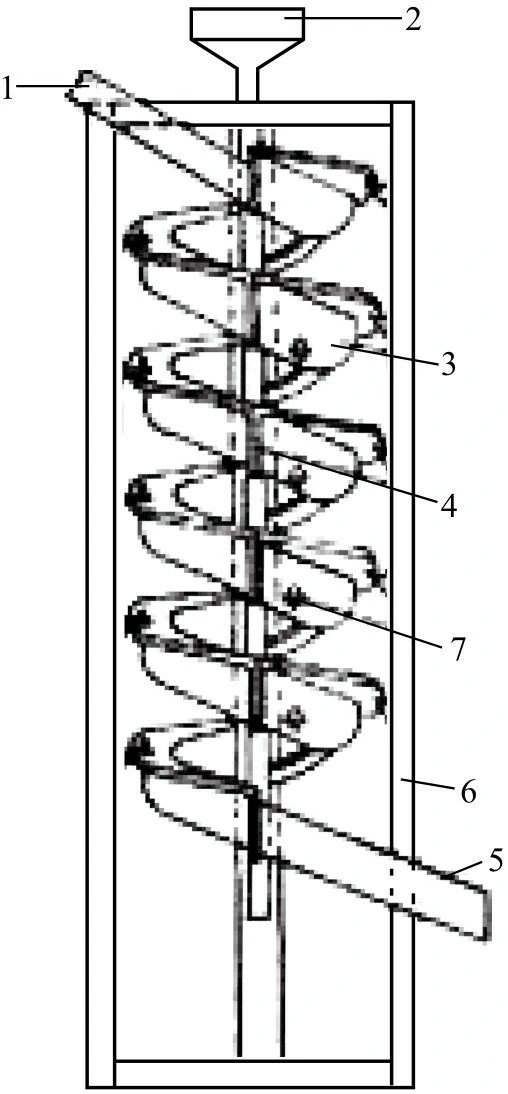

The spiral chute and spiral concentrator for alluvial gold are both spiral chute beneficiation equipment. The structure of the spiral concentrator is shown in Figure 3-5. It is made by bending a chute around a vertical axis into a spiral shape. The spiral has 3 to 5 turns and is fixed on vertical support. The section of the spiral groove is a part of a parabola or ellipse. Both the flow direction and the transverse direction (radial direction) have a certain inclination.

Starting from the second circle, there is a heavy product discharge pipe (4-6 in total) in the middle of the bottom of the tank, and an interceptor is installed on the upper part of the discharge pipe, which can intercept the flow of heavy minerals and make it discharge into the discharge pipe.

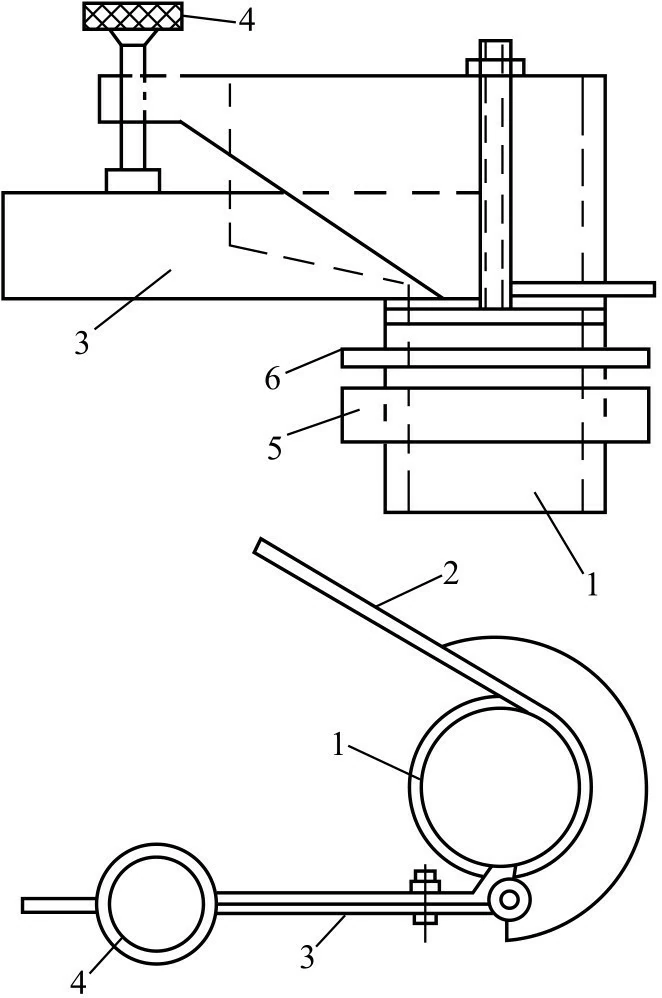

The two scrapers of the cutter are pressed against the groove surface, and the movable scraper in it can be rotated to adjust the opening angle between the two scrapers, thereby adjusting the discharge of heavy minerals, as shown in Figure 3-6 Show. In order to improve the quality of heavy products, there are several water addition points on the inner edge of the tank, called washing water, which is fed into the inner edge of the tank from a central water pipe through a valve.

1—feeding trough; 2—washing water guide trough; 3—spiral groove; 4—spiral groove connecting flange; 5—tailing discharge chute; 6—frame; 7—heavy mineral discharge nozzle

1—discharge pipe; 2—fixed scraper; 3—movable scraper; 4—compression screw; 5—nut; 6—washer

2. Technical Principle of Spiral Concentrator for Alluvial Gold

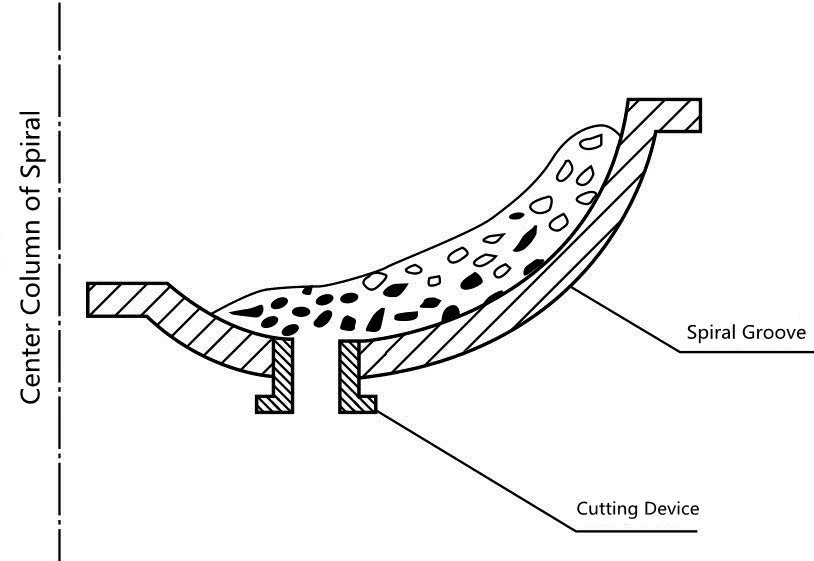

When processing, the slurry is fed evenly along the width of the groove from the homogenizer on the upper part of the tank. The slurry is stratified during the flow along the groove, and heavy minerals enter the bottom layer and move to the inner edge of the groove under the combined action of various forces.

Light minerals are thrown to the outer edge in a rapid rotational movement. As a result, the ore grains with different densities spread out across the trough, as shown in Figure 3-7. The heavy minerals flowing along the inner edge of the tank are intercepted by the interceptor and discharged through the discharge pipe.

The quality of the heavy products obtained from the first to second discharge pipes above is the highest, and the quality of the following heavy products is lower. The washing water added to the inner edge of the tank flushes part of the light minerals mixed with heavy products to the outer edge, which is beneficial to improve the quality of the concentrate. The tailings are discharged from the end of the lowest tank.

3. Operating Procedures of Spiral Concentrator for Alluvial Gold

Pay attention to the following points when operating the spiral concentrator:

- ① The maximum feed size is 6mm. When too large ore comes in, it will disturb the ore flow and block the concentrate discharge pipe. Large flakes of gangue are also detrimental to beneficiation. Therefore, use a sieve to screen out large pieces before being processed. In addition, when the processed material contains a lot of mud, the beneficiation effect will be deteriorated, so if there is a lot of mud, it must be deslimed in advance.

- ② Control the amount of ore feeding. When the concentrate contains more mud and the concentrate is finer, the amount of ore can be smaller. When the size of the concentrate is coarser and less mud, the amount of ore can be larger. The requirement for the ore concentration is not strict, and the change of the concentration within the range of 10% to 30% has little effect on the sorting index.

- ③ Washing should be distributed from the inner edge to avoid disrupting the ore flow. The washing water volume is large and the concentrate grade is high, but the recovery rate is reduced. The washing water is small, which is beneficial to increase the recovery rate. The washing water should be increased gradually from top to bottom.

- ④ The concentrate yield is adjusted by rotating the movable scraper of the interceptor. If too much concentrate is intercepted, the concentrate grade will decrease. The appropriate position of the movable scraper should be determined through sampling and examination, and then be flexibly mastered after having experience.

4. The Difference Between Spiral Chute and Spiral Concentrator

The shape and working principle of the spiral chute and the spiral concentrator are basically the same, but they are different in structure, performance and use. The main differences are as follows:

- ① The bottom section line of the spiral concentrator is a parabola or part of an ellipse, while the bottom section line of the spiral chute is a cubic parabola. Therefore, the bottom of the spiral chute is wide and gentle, which is more suitable for processing fine-grained materials.

- ② The spiral chute is to take the concentrate, medium and tailings at the end of the trough, while the spiral concentrator intercepts the concentrate at the upper part and connects the tailings at the end of the trough.

- ③ The spiral chute has no washing water, but the spiral concentrator has washing water.

- ④ The feeding particle size of the spiral chute is smaller than that of the spiral concentrator. The suitable feeding particle size of the spiral concentrator is 0.074~2mm, and the suitable feeding particle size of the spiral chute is 0.04~0.3mm.

- ⑤ Regarding the feed concentration, the spiral chute requires a high concentration, generally not less than 30%, while the spiral concentrator concentration is not strict, and the lower limit can reach 10%.

5. Features

The advantages of the two types of equipment are no moving parts, simple structure, small footprint, large processing capacity, intuitive sorting process, and easy operation.

The disadvantage is that the equipment has a relatively high external size, a large yield of concentrate, and a poor recovery effect on the spherical gold. In gold mines, these two types of equipment are mainly used to recover single or continuous gold from flotation tailings.

6. References

- Precious Metal Production Technology User Manual Edited by the Editorial Board. Precious Metal Production Technology User Manual[M]. Beijing: Metallurgical Industry Press, 2011.

- Wang Yonglu.Precious Metal Extraction and Refining[M]. Changsha: Central South University Press

Thank you for reading. What are your thoughts on Extract Gold by Spiral Concentrator? Welcome to leave a message, or contact me directly:

- Email: asa.guo1989@gmail.com

- Whatsapp & phone: +8618026978087

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of gold wash plant equipment in Asia. Don’t hesitate to Contact Us, if you have any questions about beneficiation. And welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serve you!

Responses