What Wikipedia Can’t Tell You About Placer Gold Beneficiation in Africa

OVERVIEW of PLACER GOLD BENEFICIATION in AFRICA

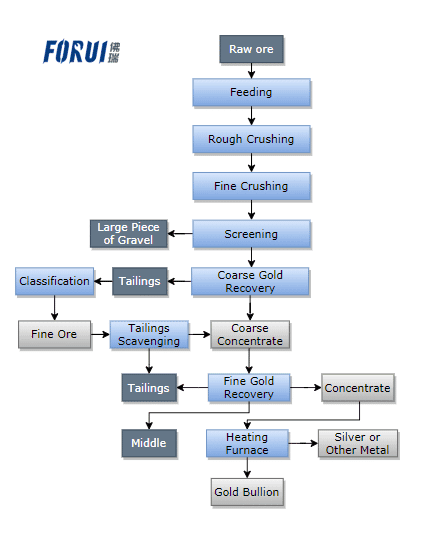

Recently, a customer needs our help to design a solution of placer gold beneficiation in Africa. First, we analyze the properties of the gold deposits according to the data provided by the customer. According to these properties, the whole beneficiation process is designed as follows.

FEEDING

First, an excavator is used to feed the ore into the hopper. After passing through the hopper, the ore enters the feeder. In order to ensure the continuous and stable operation of the whole process, we are equipped with vibrating feeder for customers. It can uniformly, regularly and continuously feed bulk and granular materials from the storage bin to the receiving device.

CRUSHING

In the beneficiation process, there are two basic processes. One is dissociation, in which a large ore is broken up so that various useful mineral particles are separated from the ore. The other is separation, which means that the separated mineral particles are sorted into different products according to their different physical and chemical properties.

The process of breaking up in our case is the process of dissociation. Of course, in general, the useful placer gold can be separated from the waste rock only by a simple crushing process.

SCREENING

After the fragmentation, most of the gold ore has been isolated monomer. At this time it is necessary to enter another basic process of beneficiation – screening.

As the customer’s placer gold deposit contains a large amount of clay, we have equipped him with a trommel screen. At the same time the trommel screen is used for screening, the gold ore can also be washed.

ROUGH BENEFICIATION of PLACER GOLD BENEFICIATION in AFRICA

After screening and washing, the next step is to enter the coarse beneficiation. Because the grade of placer gold in the gold deposit is generally low, it is necessary to carry on the coarse beneficiation first. We can use a sluice box or a centrifuge for rough beneficiation. After rough beneficiation we will get coarse concentrate and tailings.

TAILINGS SCAVENGING of PLACER GOLD BENEFICIATION in AFRICA

In order to improve the recovery rate, we should scavenge the tailings obtained after rough beneficiation. Before scavenging, tailings are graded and small pieces of gravel are discarded. Then the fine gold ore is swept. After scavenging, coarse concentrate and tailings are obtained. The tailing is so low in gold that it can be thrown away.

FINE GOLD RECOVERY of PLACER GOLD BENEFICIATION in AFRICA

Then we enter the cull process. Coarse concentrate was obtained in the previous two stages of rough and sweep respectively. We use a shaking table to refine the crude concentrate.

The beneficiation shaking table can make the ore particles move in different directions according to its density and grain size. These grains are fanned diagonally from the feed trough and discharged in turn along the edge of the bed face. The ore discharge line formed on the bed surface is very long and can produce many kinds of products with different qualities accurately. Such as concentrate, secondary concentrate, medium concentrate and tailings, etc.

HEATING FURNACE

Then, the ore and gold ore concentrate products obtained from the selection process are sent to the melting furnace for smelting. We ended up with gold and silver and other precious metals.

Above is the process flow of the placer gold beneficiation in Africa.

If you have any comments or suggestions, please feel free to leave a comment below or CONTACT US directly.

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation. And welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serve you!

Responses